Ladder Joinery

To attach the steps to the rails, you can use any butt construction such as dados, screws and plugs, or even domino tenons, depending on aesthetics and loading needs. For holding light items such as paperbacks, small plants and picture frames, I used dowels. I have developed two simple jigs that take care of all the drilling and accuracy requirements essential for this kind of project.

Making the Rail-Drilling Jig

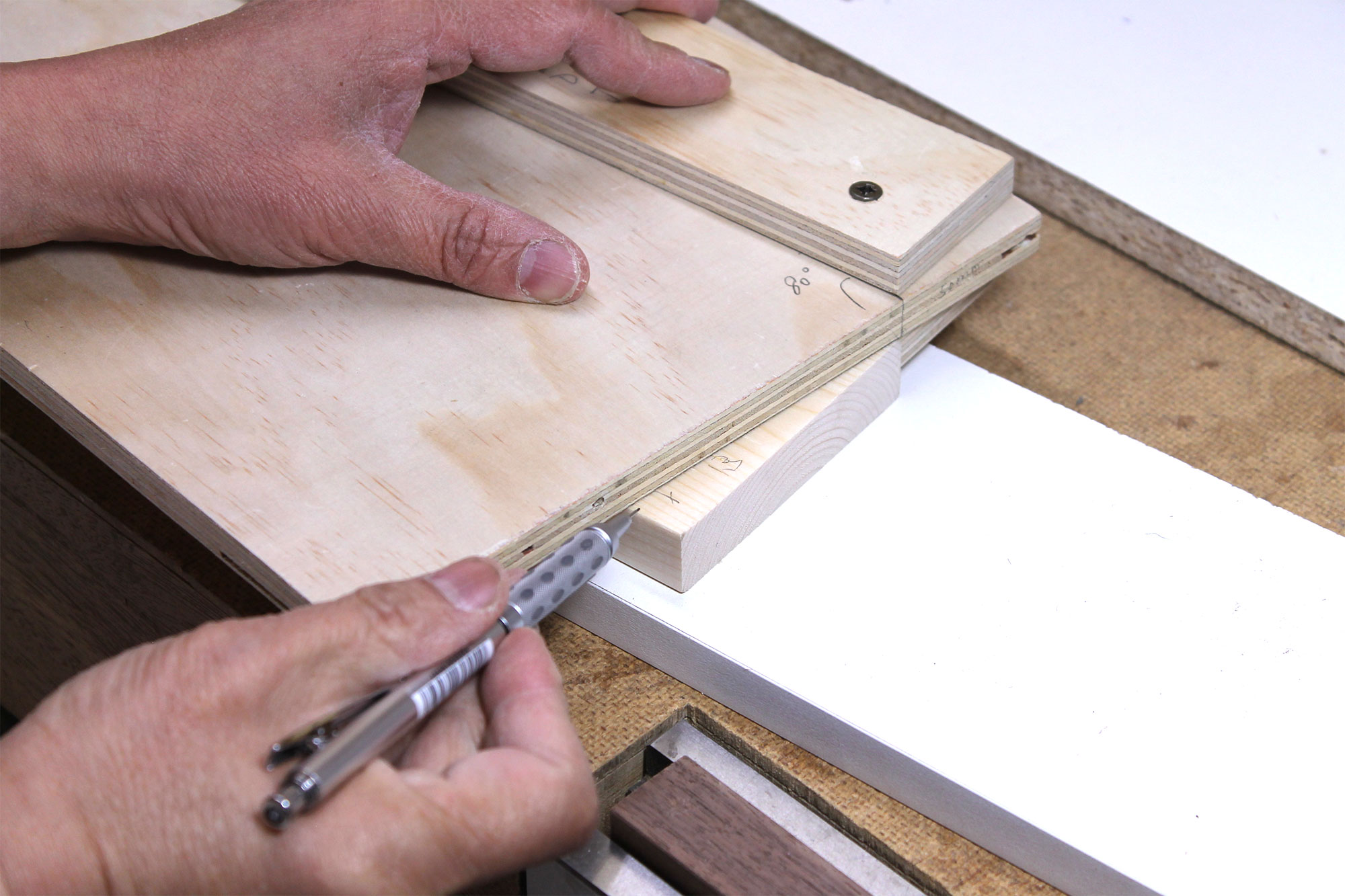

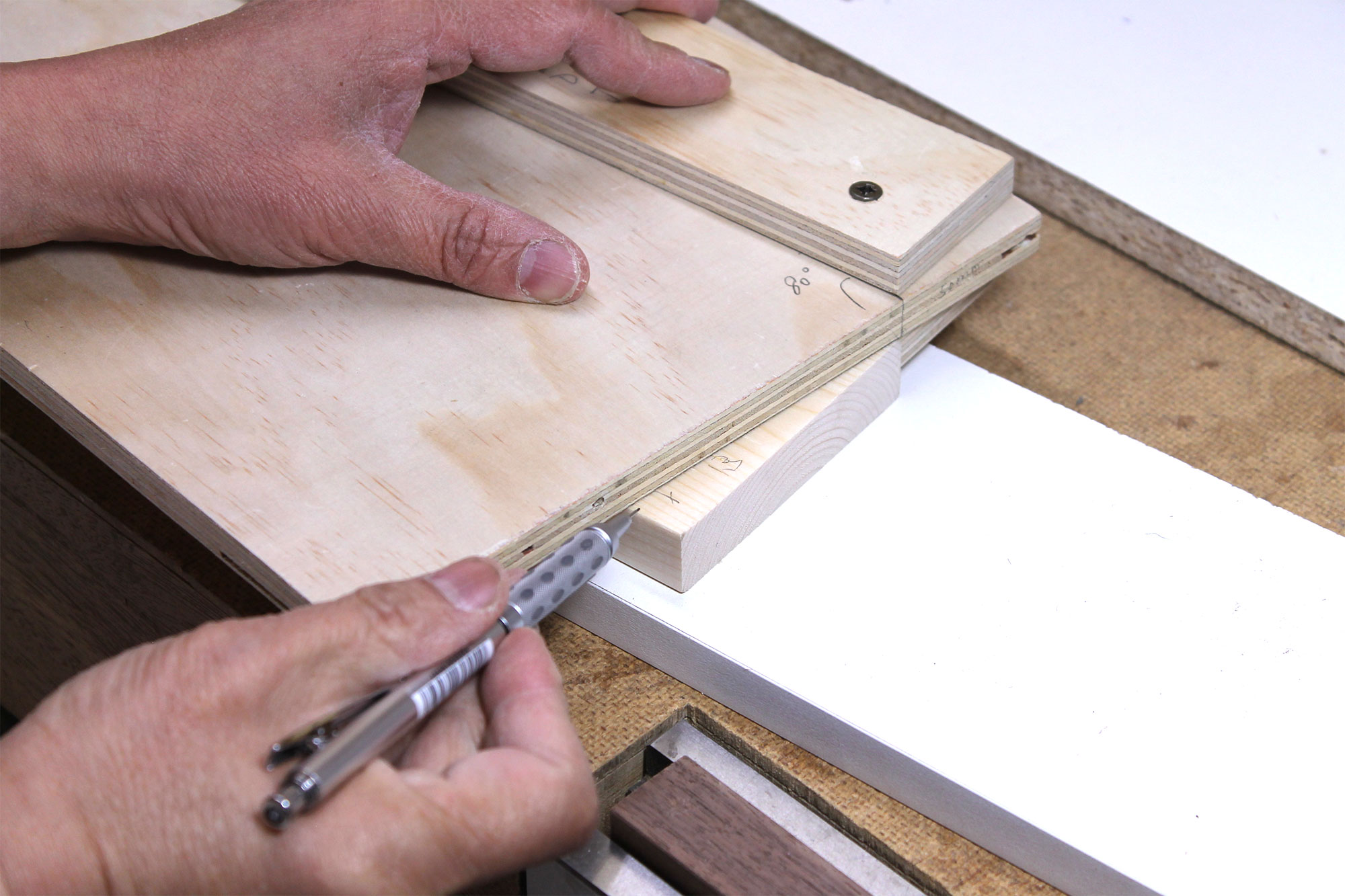

The rail jig, with dual fences, allows you to drill identical pairs of holes on opposite rails at the same angle (for instance at 80°) and by repositioning the jig on the rail at the same desired positions on both rails. To build the jig, start with some 3/4" material and lay out the desired leaning angle line on one side of the board to attach a fence. After screwing the fence in place, flip the board to install the second fence.

The author used a combination square to ensure the second fence was mounted at the identical spot on the opposite side as the first fence.

The leaning angle (80° in this example) is marked on the board for the fence installation.

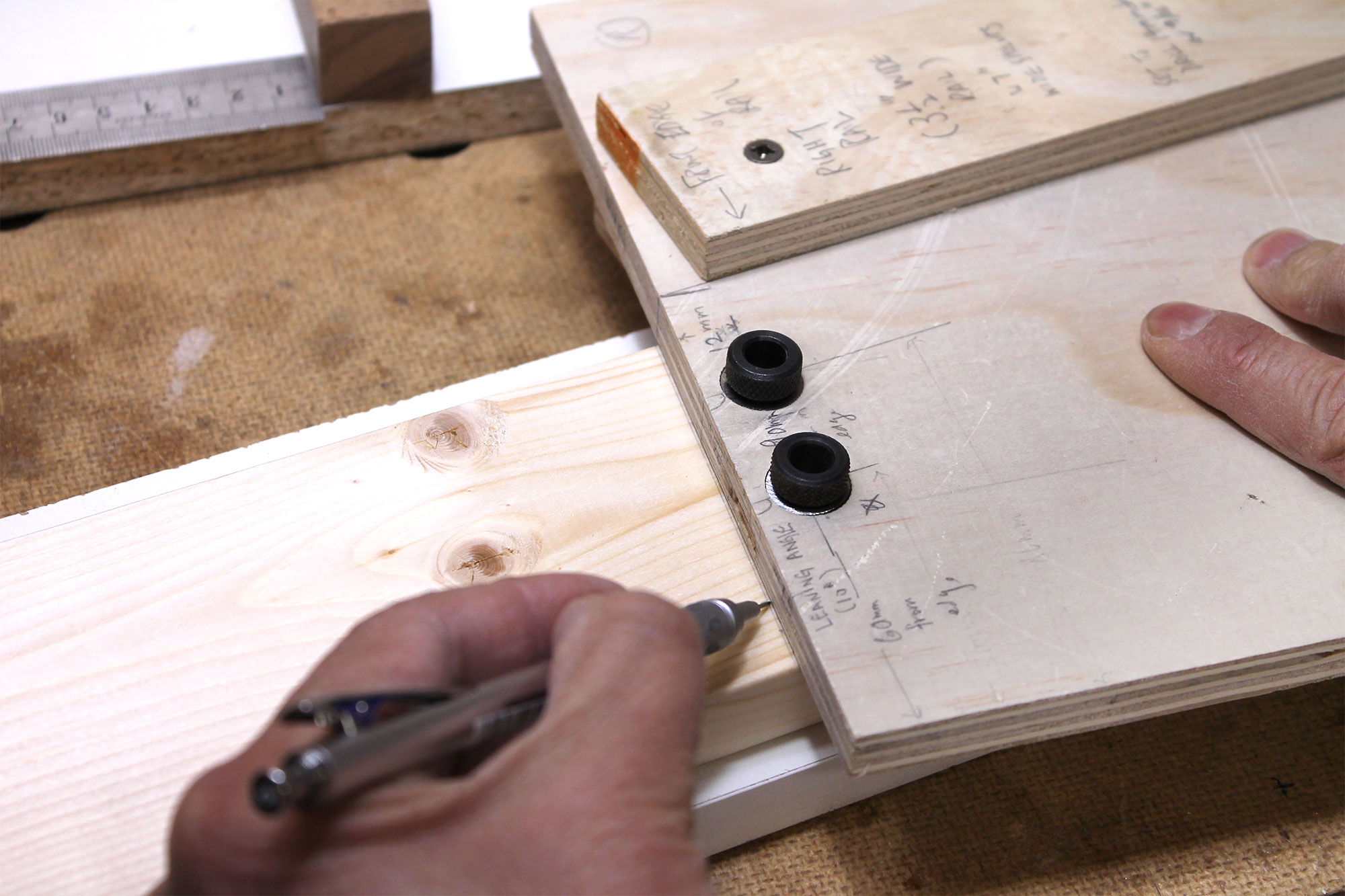

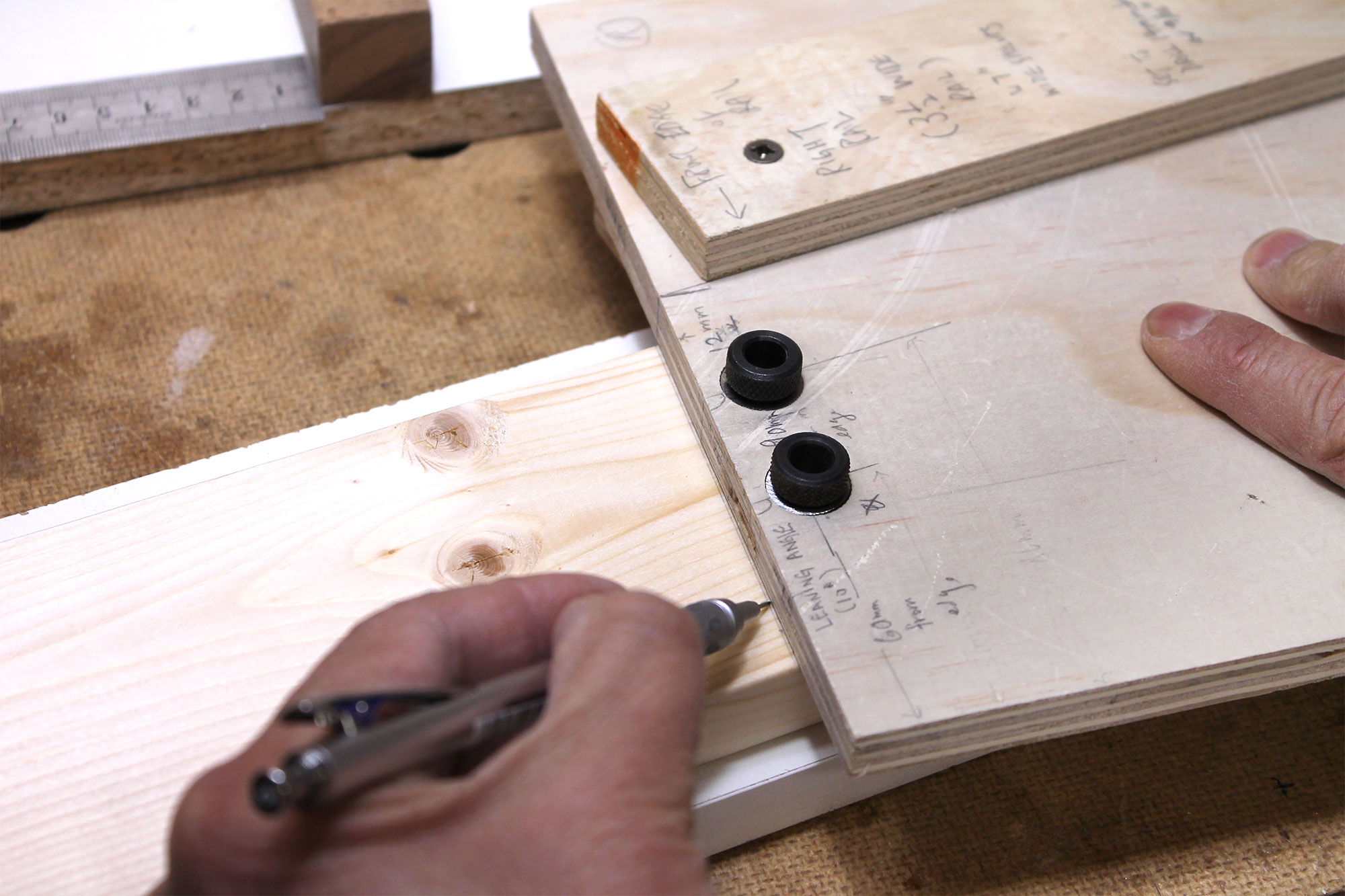

For consistency and accuracy, I used drill-guide bushings. Mark out the center points for the guide inserts on the board, drill the holes and install the guide inserts and bushings.

Label the top fence "R" or "Right" for drilling the right rail and the bottom fence "L" for the left rail.

Making the Shelf-Drilling Jig

I made the second jig for drilling matching holes on the shelf ends using a block with two holes drilled for the guide inserts spaced apart exactly as the two inserts are on the rail-drilling jig. After drilling the insert holes in the middle of the block, cut a center dado on the bottom that’s as wide as the shelf stock is thick.

Cut a snug fit dado or screw two wooden strips on the bottom to form a channel.

To complete the jig, screw two end blocks (set apart to the same width as the shelf) in the dado. The jig shares the use of the same guide bushings (5/16" dia. in this case) with the rail-drilling jig.

Use the centerlines on the shelf and jig to help position the end blocks.

Using the Rail-Drilling Jig

The first step is to lay out the angled line on the inside face of rails to locate the position of each shelf. Start with the right-hand fence (side labelled "R" facing up), registering it against the front edge of the right rail and draw a pencil line for the bottom. Use the upper end of the jig to mark the first shelf location. Move the jig up to mark the positions of the remaining shelves. Lastly, repeat the same marking steps on the left rail with the left-hand fence.

Reference the fence against the front edge of the rail and begin the marking from the bottom.

Use the top edge of the jig to lay out a new line while the bottom edge lines up with the previous line.

The two rails clamped side by side together.

Once the slope lines are completed, clamp the jig in place on the rail and start drilling (with a 5/16" dia. bit as per the guide bushings) to 1/2" deep. After boring all of the holes, trim the rail ends to the pencil line.

The author sets the drilling depth.

The rail jig can be used to guide the sawing of the rails' angled ends.

Using the Shelf-Drilling Jig

To drill dowel holes on the shelves, use the shelf jig on the ends of the workpiece and drill them with a stop block or collar to 1" deep. To prevent overheating the bit, withdraw the drill from time to time.

Keep the orientation of the shelf jig the same throughout the drilling process.

The end blocks can be repositioned in the dado to handle stock of different widths.

Assembly

After dry-fitting with dowels in place and erasing the pencil lines, glue and clamp everything. Apply a finish of your choice, if desired. In the last step, add or spray some anti-slip material to the bottom of the rails, or anchor the rail tops to the wall.

The author glued the dowels into the rails first, then fitted the shelves onto one of the rails and worked with the other rail last.

This utilitarian project is easy to build and fun to work on as a family weekend project. (Even young kids can be a great help when it comes to applying glue.) Just don't forget to sign and date the pieces if you plan to make many of them and give some away!

Photos and text by Charles Mak

Charles Mak is an enthusiastic hobby woodworker, teacher, writer and tipster. He formerly worked part-time at his local Lee Valley Tools store.